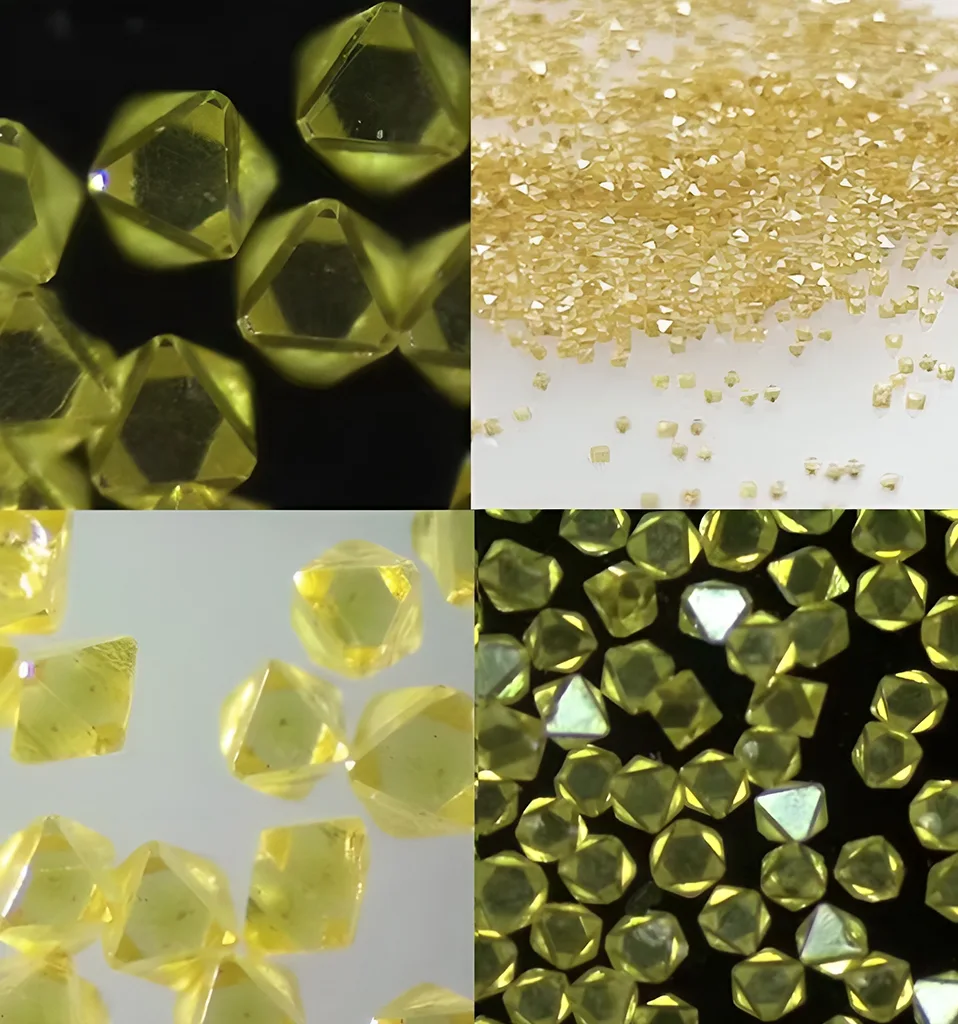

Synthetic Diamond Powder

High-purity synthetic diamond powder designed for enhanced grinding, lapping, and polishing results.

Diamond, the hardest known natural material, is composed entirely of pure carbon. While its natural form has been admired for centuries, scientists began exploring synthetic alternatives in the 18th century after confirming its carbon-based structure. It wasn’t until the 1950s that real breakthroughs occurred — thanks to advancements in high-pressure research and experimental technology — making synthetic diamond production commercially viable. Since then, synthetic diamonds have played a crucial role across various industrial sectors.

At Supreme Abrasives, we offer high-purity Synthetic Diamond Powder manufactured using two advanced techniques: High Pressure High Temperature (HPHT) and Chemical Vapor Deposition (CVD). These processes replicate the conditions under which natural diamonds form but with controlled parameters to produce uniform, reliable results.

Our synthetic diamond powder is known for its exceptional hardness, thermal stability, and consistent particle size distribution. These qualities make it ideal for a wide range of applications, including semiconductor manufacturing, high-precision grinding, polishing, cutting, and thermal management in electronics.

Applications & Industries

- Semiconductor device manufacturing

- Precision grinding and polishing

- Optical and ceramic components

- High-end cutting tools

- Thermal management in electronics

How It’s Made

Need Industrial-Grade Diamond Powder?

Reach out for quotes, technical guidance, or product specifications specialised to your industry needs.

Join industry leaders who trust Supreme Abrasives for reliable, high-performance solutions. Whether you’re scaling operations or seeking better performance tools, we’re here to help. Connect with our experts today and get a quote that fits your needs — fast, easy, and reliable.